Every project brief today mentions energy efficiency. But when it comes to the technical details, one metric often causes confusion: the R-value. It’s quoted in specifications, compared in supplier brochures, and even debated on site. Yet many construction professionals still conflate it with U-value, apply it inconsistently, or overlook its significance in South African climates.

This article provides a practical guide for project managers, architects, civil engineers, and developers. By the end, you’ll not only understand what R-values mean but also how to use them strategically in South African projects.

What we’ll cover

The Basics of R-Value

R-value measures resistance to heat flow. The higher the R-value, the better a material insulates.

- A low R-value allows heat to move through easily (like a thin summer shirt in winter).

- A high R-value slows heat transfer (like a thick, padded winter coat).

R-Value vs U-Value

- R-value = resistance (higher is better).

- U-value = rate of heat transfer (lower is better).

They are inverses: a high R-value corresponds to a low U-value. Internationally, both are used, so understanding the relationship is vital when working across standards.

R-Values in Context

Globally, R-values are a cornerstone of insulation standards:

- US: Used widely in residential and commercial construction.

- Europe: Often expressed through U-values, though the principle is the same.

In South Africa, R-values tie directly into SANS 10400-XA, which sets minimum energy efficiency requirements, and into sustainability frameworks such as Green Star SA. As local regulations tighten and energy prices rise, understanding R-values isn’t optional—it’s part of designing compliant, future-proof projects.

Where R-Values Show Up in Construction

R-values apply to multiple parts of the building envelope:

- Roofs and Ceilings: Typically the largest surface for heat loss or gain.

- Walls and Insulation Boards: Bulk insulation materials carry specified R-values.

- Floors: Especially slab-on-ground designs.

- Windows and Doors (Fenestration): Often the weakest link if poorly specified.

The Weakest Link Effect

A well-insulated wall with R=4 paired with a single-pane window at R=0.2 drastically reduces overall performance. That’s why fenestration choices carry disproportionate weight in real-world energy performance.

Practical Toolkit for South African Architects

Different regions require different performance targets:

- Coastal (Durban, Cape Town): Moderate insulation paired with solar control to manage heat gain.

- Highveld (Johannesburg, Pretoria): Stronger insulation to combat cold winters.

- Semi-arid (Karoo, Free State): Systems that balance hot days with cold nights.

Three Mistakes to Avoid

- Confusing U-value and R-value. They measure the same phenomenon but in opposite ways.

- Focusing only on glass. Frame design, seals, and installation all impact R-value.

- Ignoring installation quality. Gaps or poor sealing can reduce the effective R-value significantly.

How Fenestration Influences R-Value

Windows and doors play an outsized role in energy performance. Several elements determine their R-value:

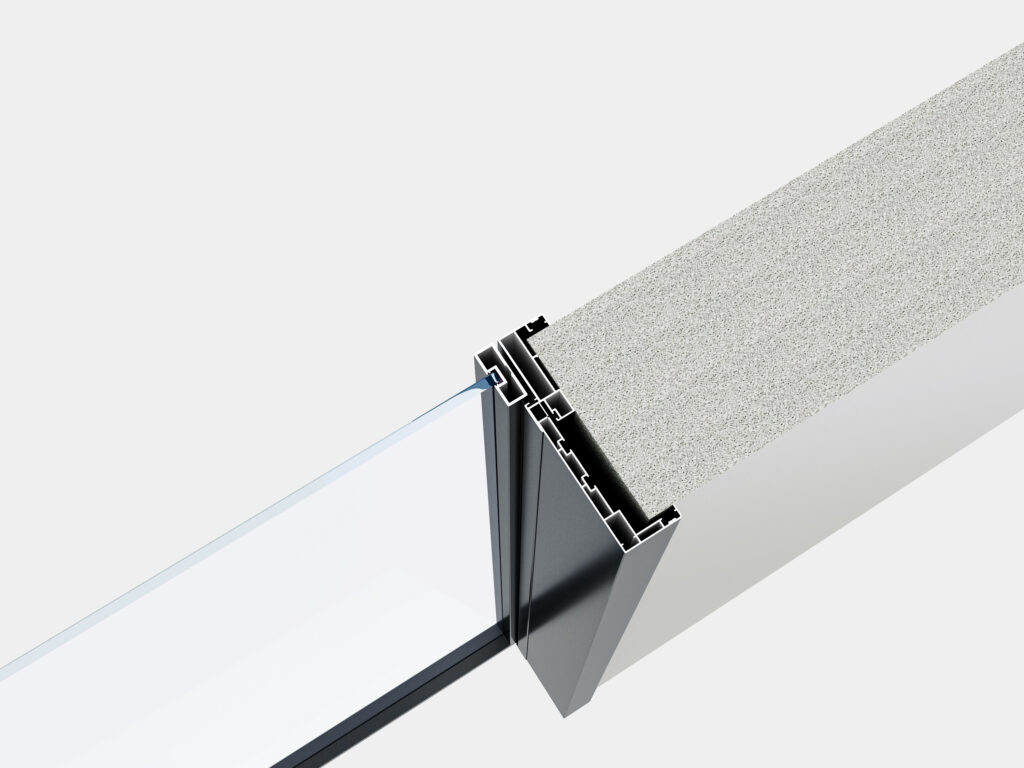

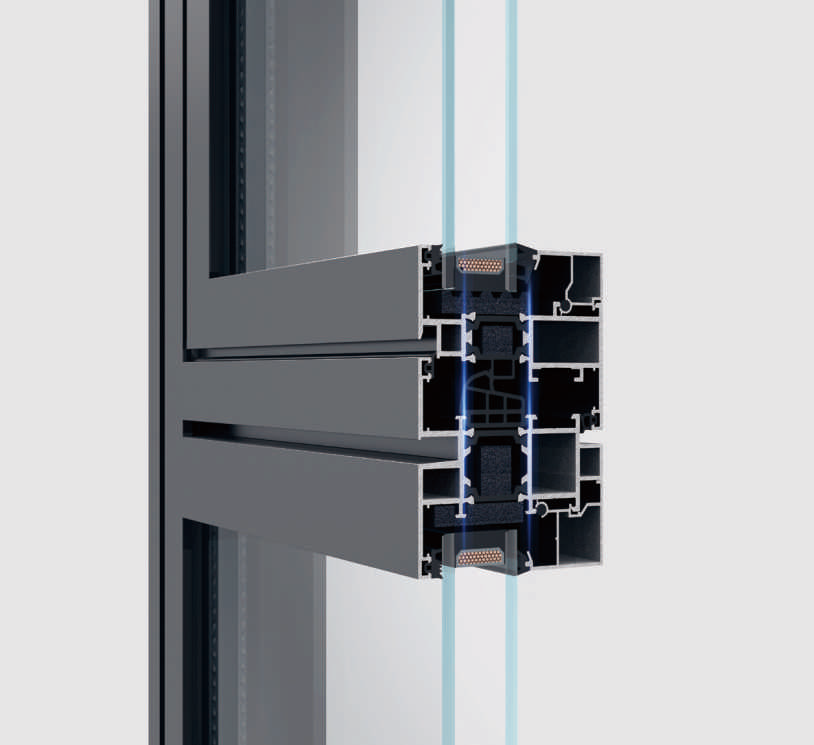

Frames: Standard aluminium has a low R-value due to high conductivity. Thermal break aluminium introduces an insulating barrier, greatly improving performance.

Glazing: Double or triple glazing with Argon gas layers slows heat transfer.

Low-E Coatings: Reflect infrared heat, improving both summer and winter performance.

Seals and Installation: Airtightness ensures the measured R-value matches real-world performance.

A complete fenestration system must balance all these elements to deliver high insulation.

Aldabra as a Case Study

While this article is primarily educational, Aldabra provides a good case study in how R-values translate into real products.

- R-value performance: ≈4.2, significantly higher than conventional aluminium windows.

- Thermal break profiles: Multi-cavity aluminium with polyamide and glass fibre barriers.

- Glazing systems: Double-glazed Low-E, laminated safety glass, Argon-filled chambers.

- Airtightness and wind resistance: Tested to Level 8 and Level 9 respectively, ensuring consistent performance under South Africa’s conditions.

This demonstrates how R-value is not an abstract number—it’s an integrated design goal achieved through materials, engineering, and testing.

Use R-Value as a Strategic Metric

For South African architects and developers, R-value is more than a compliance tick-box. It’s a strategic metric that impacts:

- Energy costs for owners and tenants.

- Occupant comfort in diverse climates.

- Regulatory compliance under SANS 10400-XA.

- Sustainability ratings in Green Star SA and beyond.

By mastering the concept, you can specify fenestration and insulation systems that elevate your projects above the minimum standard and into the realm of truly efficient, resilient design.

In every project brief, ask the question: What’s the R-value—and what does it mean for performance?