When specifying premium fenestration, the profile is everything. Aldabra’s ≥2.0 mm thermal break aluminium profiles are engineered to deliver superior energy efficiency, structural integrity, and lasting aesthetics—placing our systems firmly ahead of conventional aluminium frames.

What is a Thermal Break—and Why Should You Care?

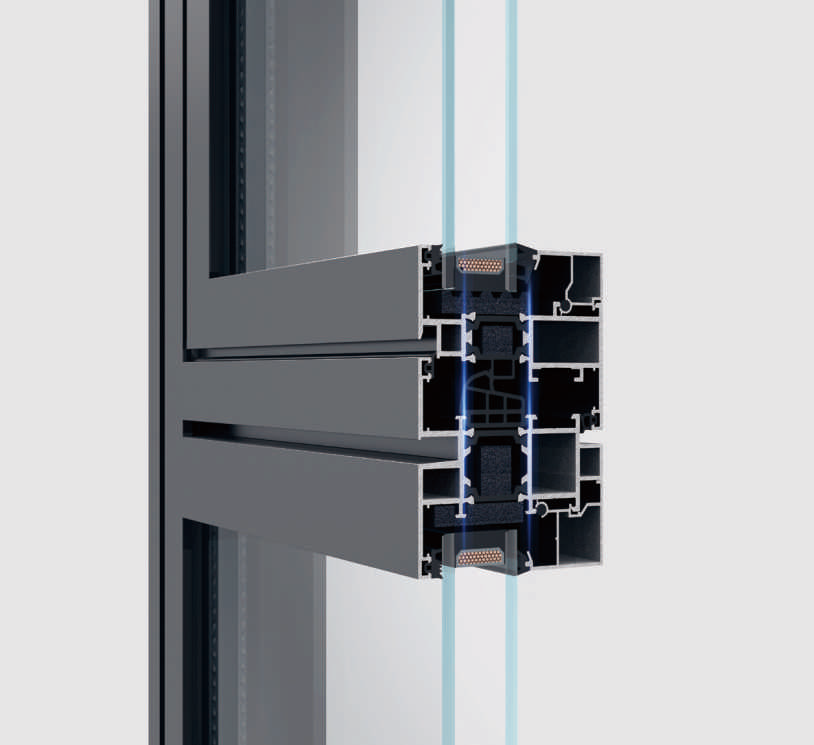

A thermal break is an insulating barrier (typically a high-performance polymer) that separates the internal and external aluminium sections of a frame. This disrupts heat flow, dramatically reducing thermal bridging—the main reason traditional aluminium frames lose energy.

In short, thermal breaks keep interiors warmer in winter, cooler in summer, and reduce the load on HVAC systems, translating to lower operational costs and improved comfort.

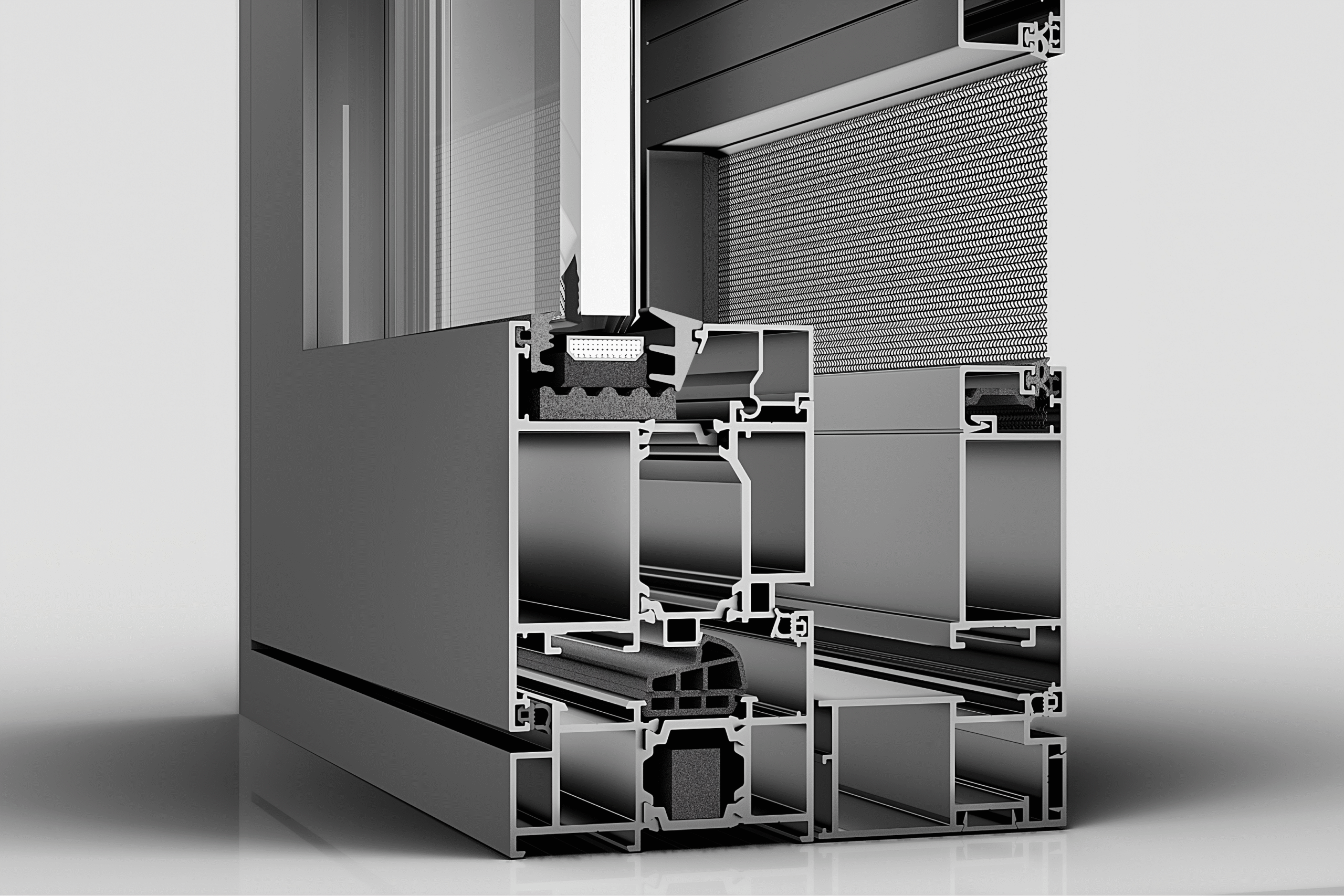

The Aldabra Difference: ≥2.0 mm Wall Thickness + Multi-Chamber Engineering

Most aluminium systems prioritise cost over performance. We don’t. Our systems use ≥2.0 mm thick aluminium walls, which provide:

- Superior structural strength for large spans, heavy glass units, and wind load resistance

- Improved durability against thermal expansion, corrosion, and mechanical stress

- Enhanced hardware anchoring—critical for long-term reliability and security

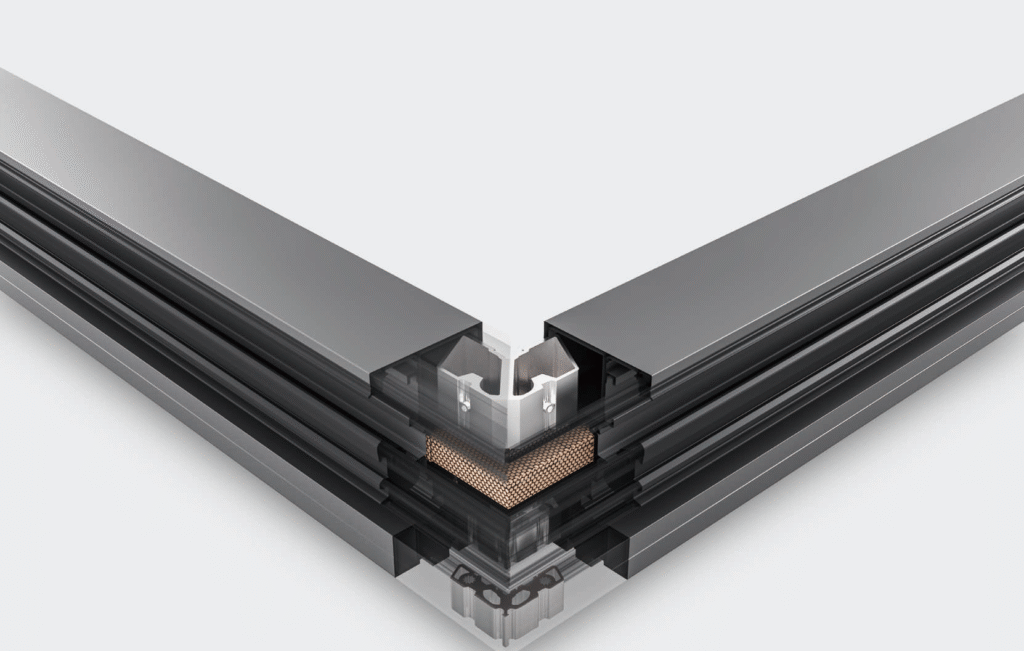

- Additionally, our proprietary multi-chamber profile design strategically reinforces the frame, optimising rigidity without compromising thermal performance.

Key Technical Advantages

- Significantly reduced heat transfer through the frame

- Minimised thermal bridging for better insulation values

- Improved condensation control—especially important in humid or cold climates

- Better acoustic performance when paired with laminated or multi-pane glazing

- High torsional rigidity for precise alignment and long-term performance

Energy Efficiency That Supports Modern Compliance & Green Design

With rising energy performance requirements in South Africa (e.g., SANS 10400-XA and green building standards), thermal break systems are no longer optional—they’re strategic. Aldabra systems help architects, developers, and homeowners achieve:

Lower U-values at the frame level (when combined with appropriate glazing)

Reduced thermal transmittance, improving overall envelope performance

Enhanced indoor comfort, particularly in extreme temperature zones

Potential points on green certifications by improving building energy metrics

Tip for architects: Pair our ≥2.0 mm thermal break frames with low-E, argon-filled IGUs to optimise whole-window performance.

Comfort Beyond Energy: Condensation, Acoustics, and Security

Condensation Control

Thermal breaks reduce dew point formation on internal frames, helping to protect finishes, reduce mould risk, and maintain better interior air quality.

Acoustic Performance

Heavier aluminium sections combined with multi-chamber design and advanced glazing result in noticeably better sound attenuation, ideal for urban or high-traffic environments.

Security & Hardware Reliability

Thicker aluminium walls and reinforced chambers mean hardware fixings are more secure, improving locking strength, sash stability, and long-term operability.

Designed for Longevity & Aesthetics

Aldabra profiles are engineered to look as good as they perform. With crisp sightlines, slim profiles, and robust finishes, our systems bridge the gap between architectural elegance and technical performance—suited to both timeless luxury homes and modern commercial façades.

Lifecycle Value: Buy Once, Buy Right

While thermal break aluminium systems may cost more upfront than standard aluminium frames, the total lifecycle value—from energy savings and reduced maintenance to durability and building performance compliance—makes Aldabra the smart long-term choice.

Frequently Asked Questions

Standard aluminium frames conduct heat freely, causing energy loss and condensation. Thermal break aluminium separates inside and outside with an insulating barrier, significantly improving performance.

A thicker section means greater strength, stability, and durability—critical for large spans, multi-point locking, and long-term performance.

Yes. By reducing heat transfer, the interior frames stay closer to room temperature, reducing the risk of condensation and mould growth.

Absolutely, thermal break systems are highly suited for achieving SANS 10400-XA compliance and can help meet green building targets.

If you value comfort, compliance, energy savings, and long-term durability, the answer is almost always yes.Are thermal break aluminium frames worth the premium?